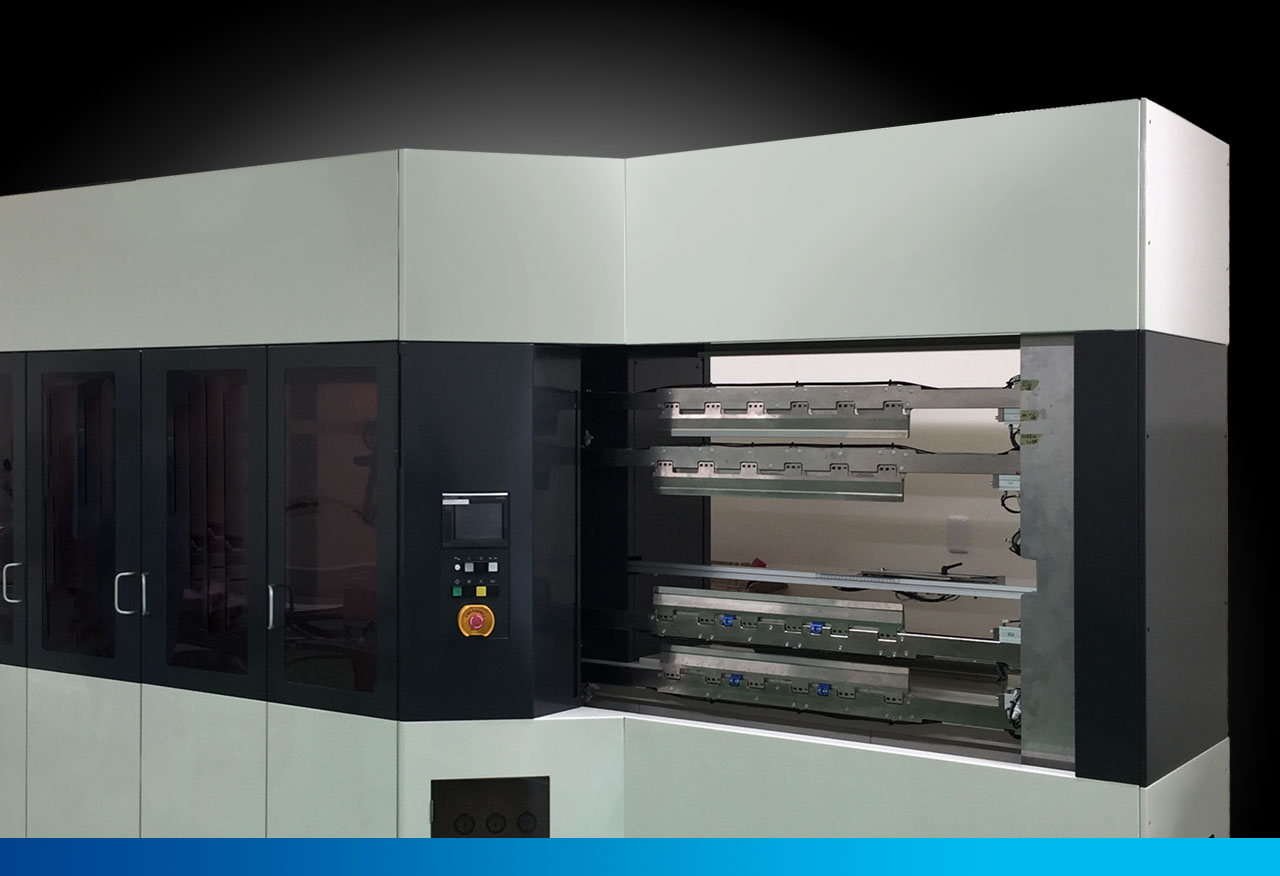

Semi-Automatic Double Side Vertical Screen Printer

|

Special double side resist printing model for printed circuit board.

|

|

|

Vertical mechanism greatly saves intallation space. Automatic line is also possible.

|

|

|

Reflect convenience functions and greatly from history and achievement of SERIA screen printing machine.

|

Basic Specifications

| Max.Work Size | (W)650×(D)650㎜ |

| Min.Work Size | (W)250×(D)250㎜ |

| Work Thickness | t0.2-3.0㎜ *The thin board with less than 0.3mm thickness may not be applicable depending on the board condition. |

| Max.Work Weight | 4kg |

| Print Margin(Space) | Min.5㎜(Squeegee Bias Unused) It Does Not Apply When You Use Squeegee Bias. |

| Frame Size | (W)1100×(D)1100㎜ t30-40㎜ |

| Frame Positioning | X ±10㎜ / Y ±10㎜ |

| Print Direction | From Top to Bottom |

| Peel Off Stroke | 20㎜ Air Cylinder Type |

| SQ.Back SC.Pressure | 0.1-0.5MPa Manual Setting With Pressure Gauge |

| SQ.Angle | ±30° |

| SQ.Speed | 25-250㎜/sec Parameter Setting |

| SQ.Stroke | 800㎜ |

| Coat Direction | Print From Bottom to Top |

| Coat Pressure | 0.1-0.5MPa With Pressure Gauge |

| Coat Speed | 25-250㎜/sec Parameter Setting |

| Coat Stroke | 800㎜ |

| Clearance Stroke | (Approx.)10㎜ With Gap Adjustment Function(Front) Fine Adjustment Amount 0-3㎜ |

| Machine Dimensions | (W)3917×(D)1145×(H)2232㎜ |

| Machine Weight | (Approx.)2000kg |

| Power Supply | 3Phase AC200V 60Hz 1kW |

| Air Supply | 50ℓ/min 0.55MPa |

Option Specifications

| Double Slide Work Carrier | Work Removing and Setting is Possbile in Printing |

| SQ.Electric Down Stop | Down Stop Stroke with Parameter Setting |

| SQ.Auto Printing Pressure Control | Printing Pressure Control with Parameter Setting |

| Peel-Off (Electric Drive) | CAM and Servo Motor Drinving |